RottoX Dynamic Wall Seal Temp

Available in 7 days, delivery time 1-3 working days

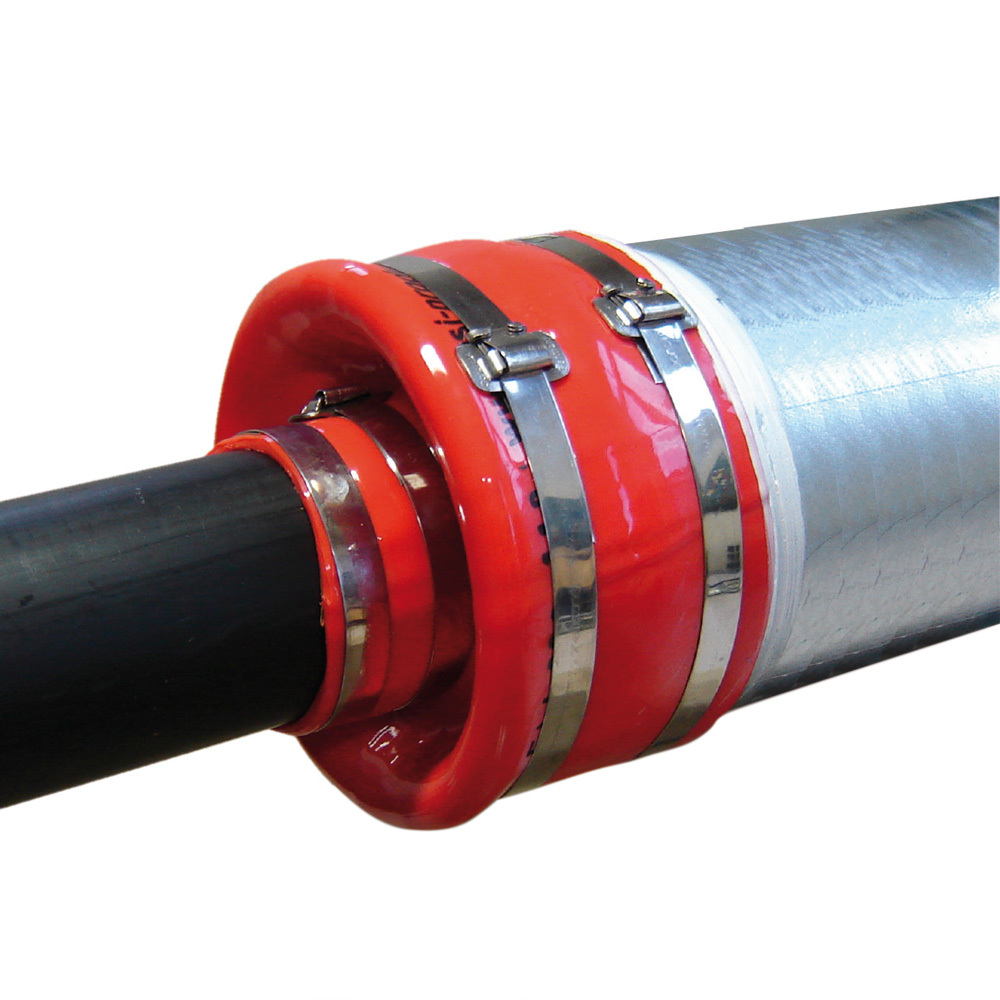

| The RottoX Temp end seals for pre-insulated pipes are specially developed to provide a pressure-tight seal between carrier and casing pipes. |

| Shore hardness | Shore A 50 ° ±5 |

| Color | red |

| Tensile strength; | 11 N/mm2 |

| Elongation at break | 400 % |

| Tear strength | 27 N/mm2 |

| Operation temperature | 55 °C |

| schweissbar | only split version |

| For installation in the ground, the sleeve must be covered with an expansion pad, to reduce the pressure of the soil on the sleeve, so that a moving during the backfilling process is still possible. To ensure tightness of RottoX Temp, the annular space should not be larger than 70 mm |

| Size | 50 x 125 mm |

|---|

Features

Due to their high flexibility, the casing end seal allows axial and radial movements between casing and carrier pipe.Areas of application

Sleeve for sealing pre-insulated pipes or other moving pipes for wall penetrations.Description

Due to the unique manufacturing process, the seamless production is possible for nearly all pipe combinations and sizes. Installation is very easy due to the pre-formed sleeves. As a result of seamless production, without punched openings, subsequent tensions will not cause cracks. Even the weld seam of the split version has the same properties in the base material, it is hot-plate-welded without any additional materials. This could be carried out on site by our partner. The material Rottolin is also characterized by high durability and flexibility. This is particularly important, for example, when used in acidic soils. Of course, this also applies to the standard STM sleeve for installation on a carrier pipe / casing pipe combination.Assembly Instructions

| 1 | Pull sleeve over the carrier pipe and the casing pipe. The edge of the casing pipe should be chamfered. Install the first strap about 15 mm in front of the end of the casing pipe. |

| 2 | Inject the adhesive included in the delivery all round underneath the sleeve. |

| 3 | Then install the second strap. Spread leaking adhesive, if necessary. |

| 4 | Align the sleeve on the carrier pipe elongated (figure a) or S-shaped (figure b) depending on the extension direction.Then install the first strap about 15 mm away from the rear end. |

| 5 | Inject the adhesive underneath the sleeve the way you did with the casing pipe side and install the second strap. Spread leaking adhesive, if necessary. |

| 6 | Finally, the sleeve has to be protected by means of an expansion pad. |

|

|

|

PSI Products GmbH

Ulrichstrasse 25

72116 Mössingen

Telefon: 0 049 (0)7473 37 81 0

E-Mail: vertrieb@psi-products.de