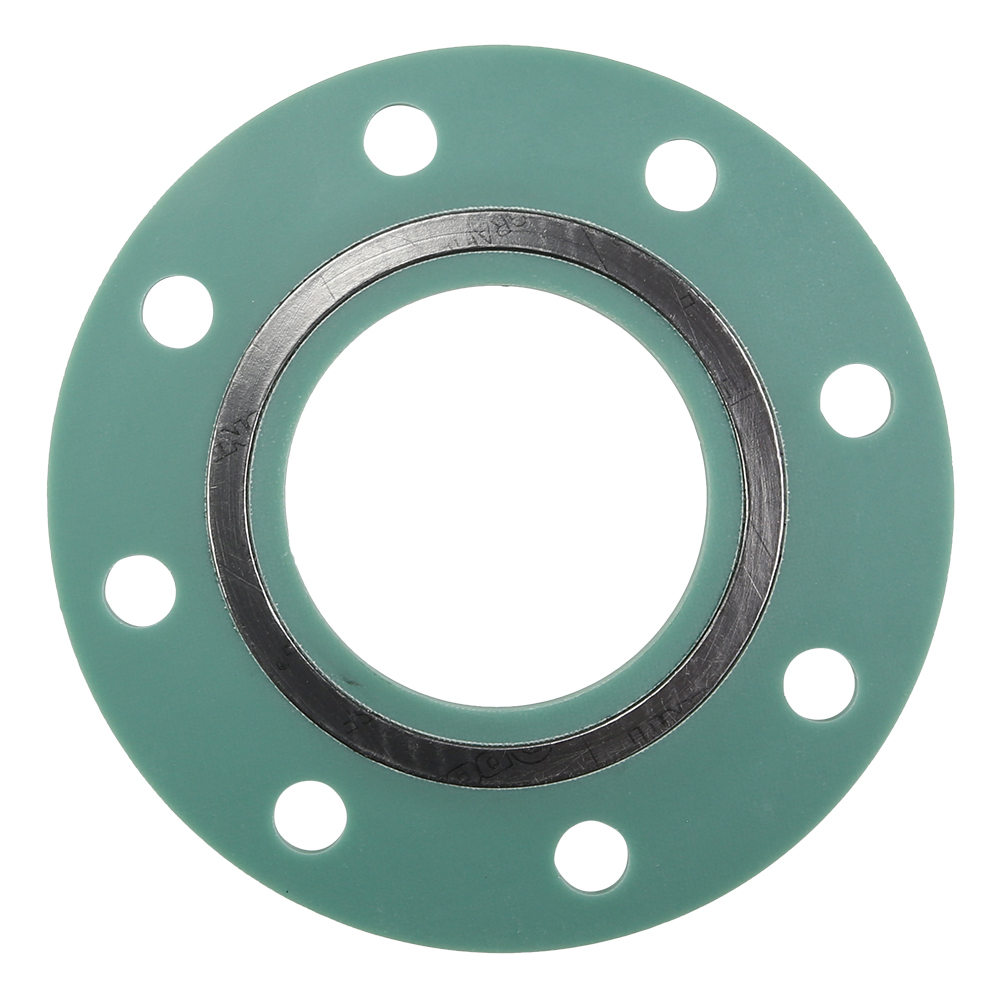

GLV UniSeal® GGR E - Flange isolation/gasket

Available, delivery time: 1-3 working days

| Sealing of flange connections in the field of gas supply; tank installation; oil supply; and electrical separation. |

| Retainer | epoxy resin bonded glass filament laminate |

| Sealing elements | expanded graphite |

| Thickness | 4 mm |

| Impact strength | 33 J/m2 |

| Short-term max. temperature | 180 °C |

| Specific contact resistance | 10 ex 16 |

| Dielectric strength | 13 kV/mm |

| Bending strength 80° C / 180°C | -/150 Mpa |

| Density | 1,9g/cm3 |

| Tensile strength; | 240 Mpa |

| Compressive strength | bis zu 500 MPa |

| Operating temperature | -60 °C bis zu +150 °C |

| Description | Indirect bolt force load flange insulating gasket ulfills the requirements of the technical rules for flammable gases and liquids functionally safe blow-out safe due to chambered sealing rings inside grooves gasket type E with bolt holes according to the flange standards gasket in design type F without bolt holes according to the flange standard (IBC Inner Bolt Circle) |

| Level of pressure | PN 10/16/25/40 |

|---|---|

| Pipe dimension (ND) | 25 |

Features

High operational safety Low tightening torques Dimensional stability Large operating temperature rangeAreas of application

Sealing and isolation of flange connections in corrosion protection plants, for electrical separation. Flange Isolation for cathodic corrosion protection of flange sealing surfaces in combination with isolation sleeves and isolation washers. Flange Isolation to meet the requirements of technical regulations for flammable gases and liquids. The flange gaskets GLV-UniSeal® T and GGr can, of course, also be used as gaskets without Isolation.Description

Easy and quick installation. Can be mounted with " standard tools" and torque wrench.

Assembly Instructions

| 1 | Clean flanges. |

| 2 | Insert gasket between flange faces. |

| 3 | Insert isolating sleeves in bolt holes. Isolation sleeve length to be calculated as follows: 2x flange thickness including raised face + 1x thickness of the flange isolation + 2x thickness of the isolation washer. |

| 4 | (If using stud bolts run one nut on one end until end of nut is flush with stud bolt). Place one steel washer and one isolating washer over bolt and insert in bolt hole. |

| 5 | Fit one isolating washer and one steel washer on protruding bolt end. Hand-tighten the nuts. |

| 6 | In order to achieve an even distribution of pressure at the flange sealing ring we recommend to tighten the bolts as shown above until the flange faces and the sealing ring are in contact. |

| 7 | Tighten bolts alternately across the diameter of the flange (see drawing above). |

| 8 | Do not overtighten or leakage may occur |

| 9 | Do not overtighten or leakage may occur |

| 10 | Ensure that bolts are well lubricated. No grease on sealing surfaces. |

| ! | The example shows 24 bolts. With flanges having a different number of bolts you should generally follow the same procedure. In order to achieve an even distribution of pressure at the flange sealing ring we recommend tightening the bolts as shown above until the flange faces and the sealing ring are in contact.

Please take the torque moments from the chart on the left. Please ensure that the bolts are greased/ lubricated sufficiently so as to avoid damage to the threads by friction. In gas applications, it is advisable to use a PTFE based grease to ensure good readings when measuring gas with gasometers. The max. tightening torques are calculated at 85% of the apparent yield point with coefficient to friction from μ = 0.140 slightly lubricated.

If relatively soft and flexible gaskets are used and tightened in a cold condition, the sealing material may relax when the system is put into operation, and the bolts may turn loose. We therefore recommend to retighten the bolts after the operating temperature has been reached - if possible without the operating pressure and at ampiente temperature. In any case the bolts should be chekked and re-tightened, if required, after the initial operation and before bringing the system back from ambiente temperature to the operating temperature. |

| Attention | The utilization of a screw recommended ≥ 8.8 with the max. tightening torque on DIN-flanges could deform the flange face. We advise to use 80% of the max. tightening torque for the bolts. |

|

|

|

PSI Products GmbH

Ulrichstrasse 25

72116 Mössingen

Telefon: 0 049 (0)7473 37 81 0

E-Mail: vertrieb@psi-products.de